|

№n/n |

Ref |

Designation |

Value |

|

1 |

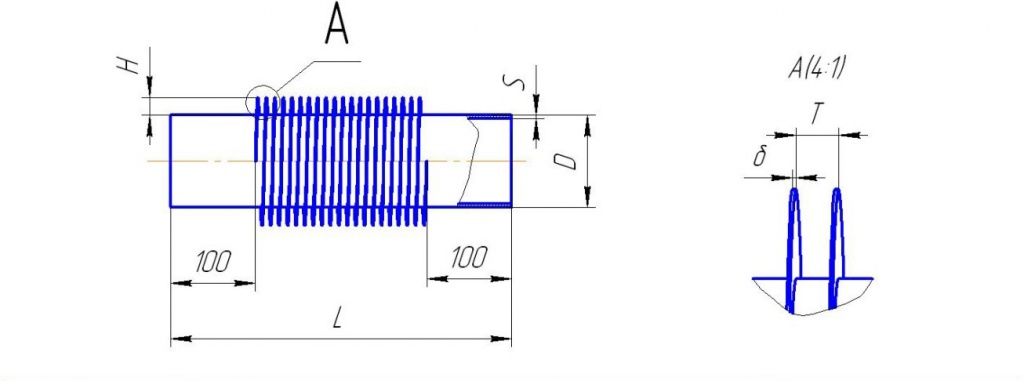

D |

Bare tube diameter by GOST 8732-78, mm |

89…315 |

|

2 |

S |

Wall thickness, mm |

1.8…8 |

|

3 |

H |

Ribbon width, mm |

6…15 |

|

4 |

δ |

Ribbon thickness, mm |

0.8…1,5 |

|

5 |

T |

Fin pitch, mm |

from 5 |

|

6 |

L |

Maximal tube length, mm |

900 |

Finned tube general drawing.

GENERALDATA

Finned tube applied in heat exchangers (heat utilizers, heaters, calorifers, economizers, air cooling condensers, product coils) in energetics, oil treating, chemical and other industries.

features

Finning is conducted by high frequency continuous root zone welding between ribbon and tube. In result the object receives list of following features:

- heat transfer coefficient increases up to 50 %;

- heating surface service life increases in 2 – 3 times;

- general reduction of heat exchanger weight by 30…40 %;

- reduction of pipe quantity by 50% in comparison with bare tube models.

Finned tube material match

|

№ п/п |

Steel grade |

|

|

|

Tubes |

Ribbons |

|

1 |

10 |

0.8 |

|

2 |

20 |

0.8 kp |

|

3 |

09G2S |

0.8 ps |

|

4 |

10G2 |

10 |

|

5 |

12H1MF |

10 kp |

|

7 |

12H1MF, 12MH, 15HM |

12H1MF |

|

8 |

08H18N10 |

08H18N10T |

|

9 |

08H18N10Т |

08H18N10 |

|

10 |

08H18N12T, 12H18N12T, 12H18N10T |

08H18N10T |