GENERAL DATA

Chemical injection unit BDR is intended for in taking, storing and dosed injection of chemicals into feed lines and other processing units at oil and gas production facilities.

EQUIPMENT MODIFICATION

To order it is possible to manufacture the injection units UD, BR, BDR in any other configuration (number of pumps, pump delivery, pressure, tank volume).

BDR features

Operating conditions should correspond to U, HL by GOST 15150-69.

Placement category – 1by GOST15150-69.

Process room classВ-1а.

Common specifications

|

Parameter |

Value |

||||

|

BDR-10 |

BDR-3 |

BDR-2.5 |

BDR-2 |

BDR-1 |

|

|

Operating chemical injection pressure, max, MPa (kgf/cm2) |

10.0 (100) |

10.0 (100) |

10.0 (100) |

2.5 (25) |

10 (100) |

|

Single pump maximal delivery, l/hr |

10 |

16 |

2.5 |

40 |

10 |

|

Number of injection pumps: - operating; - reserve. |

1 1 |

2 1 |

1 1 |

2 1 |

1 1 |

|

Process tank volume, m3 |

2.5 |

3.0 |

2.0 |

2.0 |

2.0 |

|

Number of process tanks |

1 |

2 |

1 |

2 2 |

1 1 |

|

Power consumption, kW |

10 |

10 |

8 |

16 |

12 |

|

Mass, kg, max |

2000 |

3215 |

2200 |

3500 |

2000 |

|

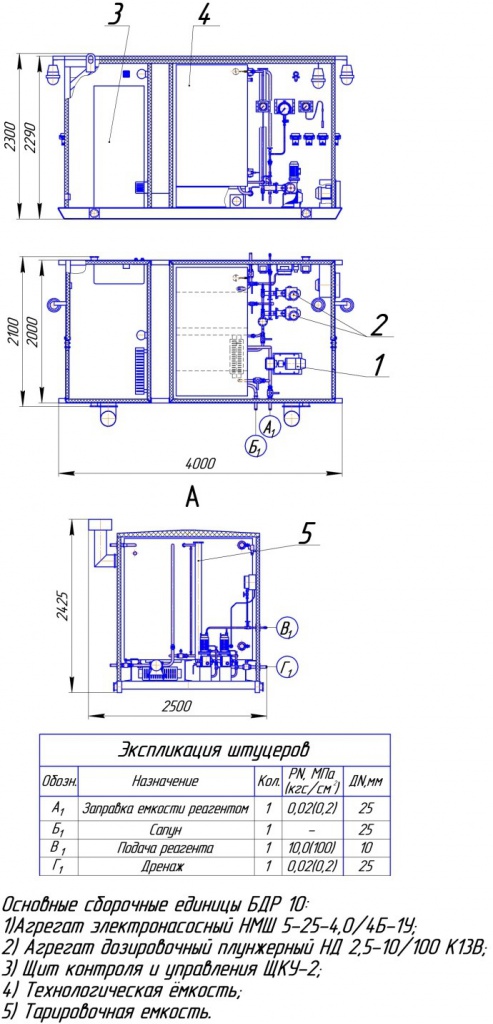

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Chemical loading |

1 |

0.02 (0.2) |

25 |

|

Б1 |

Vent |

1 |

- |

25 |

|

В1 |

Chemical supply |

1 |

10.0 (100) |

10 |

|

Г1 |

Drainage |

1 |

0.02 (0.2) |

25 |

BDR-10 basic assembly units:

1) NMSh 5-25-4.0/4B-1U electric pump;

2) ND 2.5-10/100 K13V measuring piston unit;

3) SchKU-2 control panel;

4) process tank;

5) rating tank

BDR-10 general drawing.

|

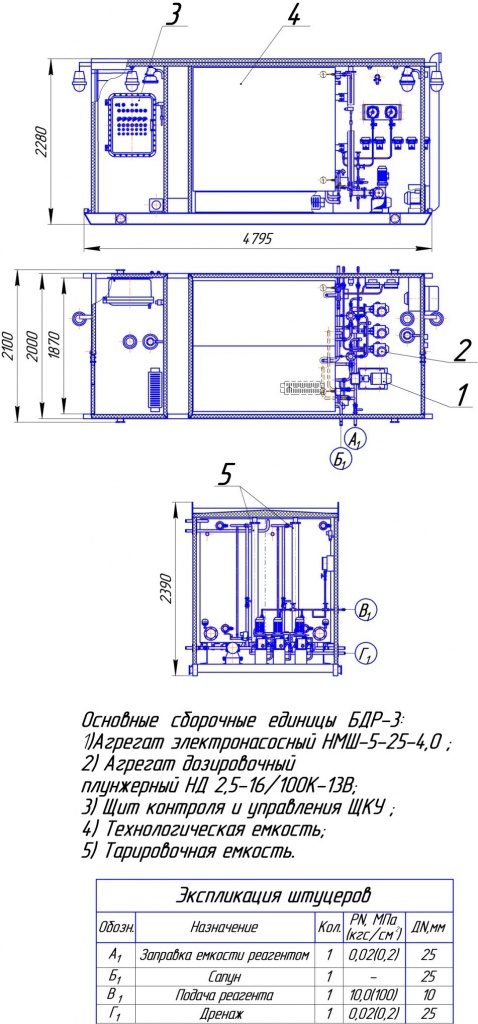

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Chemical loading |

1 |

0.02 (0.2) |

25 |

|

Б1 |

Vent |

1 |

- |

25 |

|

В1 |

Chemical supply |

1 |

10.0 (100) |

10 |

|

Г1 |

Drainage |

1 |

0.02 (0.2) |

25 |

BDR-3 basic assembly units:

1) NMSh 5-25-4.0 electric pump;

2) ND 2.5-16/100K-13V measuring piston unit;

3) SchKU control panel;

4) process tank;

5) rating tank

BDR-3 general drawing.

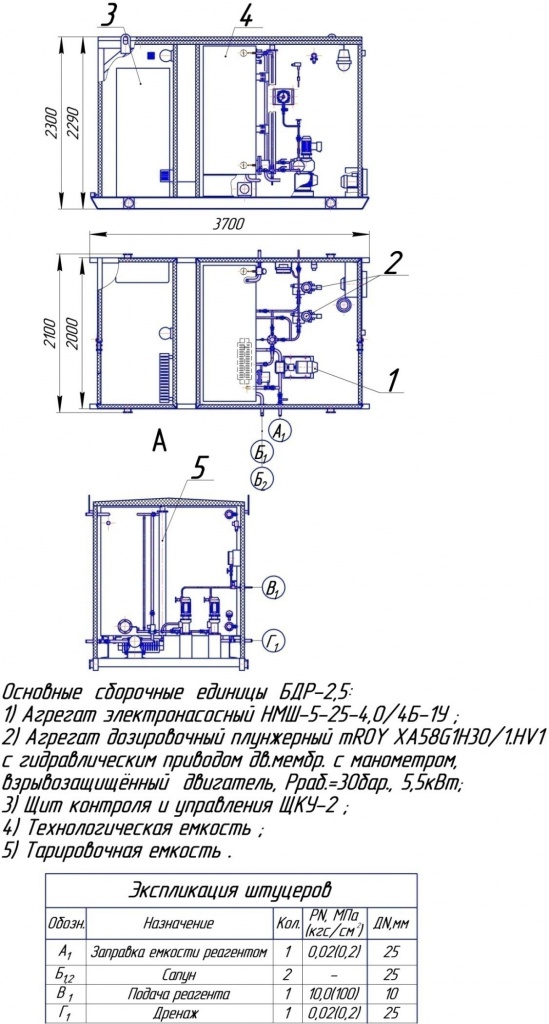

BDR-2.5 basic assembly units:

1) NMSh 5-25-4.0/4B-1U electric pump;

2)

Measuring piston unitm ROY

XA58G1H30/1.HV1

(diaphragm hydraulic drive, manometer, flameproof motor,

Pwork= 30 bar, 5.5 kW);

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Chemical loading |

1 |

0.02 (0.2) |

25 |

|

Б1,2 |

Vent |

2 |

- |

25 |

|

В1 |

Chemical supply |

1 |

10.0 (100) |

10 |

|

Г1 |

Drainage |

1 |

0.02 (0.2) |

25 |

1) SchKU-2 control panel;

2) process tank;

3) rating tank

BDR-2.5 general drawing.

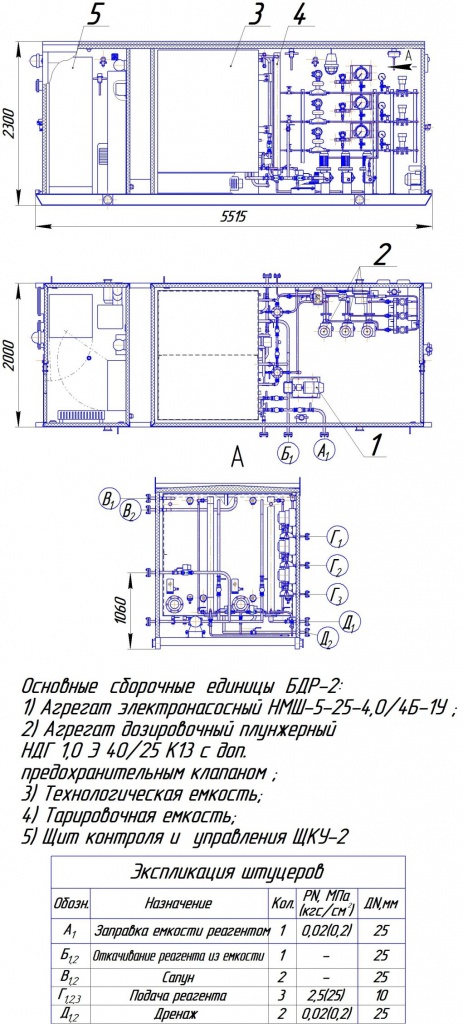

BDR-2 basic assembly units:

1) NMSh-5-25-4/4B-1U electric pump;

2)

Piston measuring unit NDG

1.0 E 40/25 K13

with additional safety valve;

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Chemical loading |

1 |

0.02 (0.2) |

25 |

|

Б1,2 |

Chemical offloading |

1 |

- |

25 |

|

В1,2 |

Vent |

2 |

- |

25 |

|

Г1,2,3 |

Chemical supply |

3 |

2.5 (25) |

10 |

|

Д1,2 |

Drainage |

2 |

0.02 (0.2) |

25 |

1) process tank;

2) rating tank;

3) SchKU-2 control panel

BDR-2 general drawing.

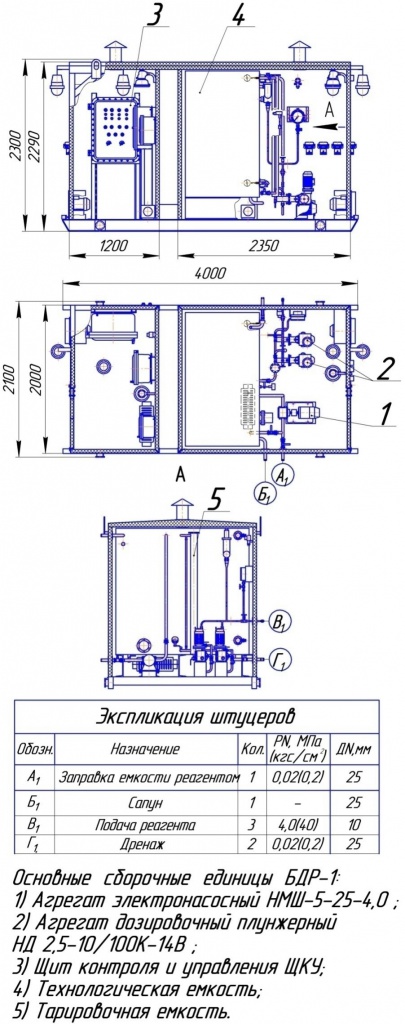

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Chemical loading |

1 |

0.02 (0.2) |

25 |

|

Б1 |

Vent |

1 |

- |

25 |

|

В1 |

Chemical supply |

3 |

4.0 (40) |

10 |

|

Г1 |

Drainage |

2 |

0.02 (0.2) |

25 |

BDR-1 basic assembly units:

1) NMSh-5-25-4.0 electric pump;

2) ND 2.5-10/100K-14Vpiston measuring unit;

3) SchKU-2 control panel;

4) process tank;

5) rating tank

BDR-1 general drawing.