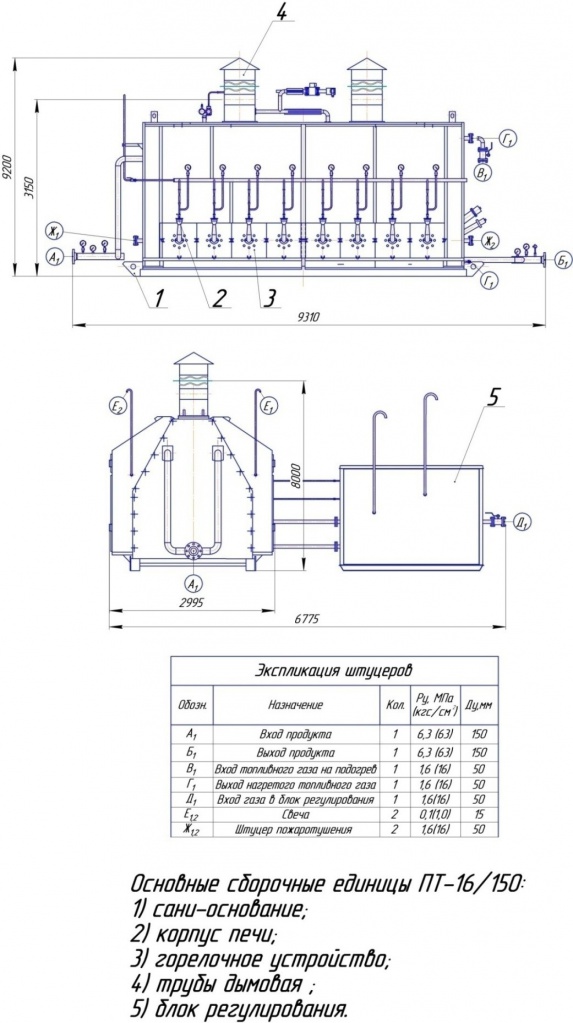

PT-16/150 general layout.

GENERALDATA

Automated modular heater intended for heating of oil emulsions, oil and gas at gathering, treating and transporting facilities, as well as for water heating.

features

Climatic modification – U, HLby GOST 15150-69.

Placement category–1 by GOST15150-69.

Common specifications

|

Parameter |

Value |

||

|

PT-25/100 |

PT-16/150 |

PT-6.3/200 |

|

|

Rated heat capacity, MW (Gcal/hr) |

0.6 (0.7) |

1.9 (1.6) |

4.2 (3.7) |

|

Heated product related productivity, kg/sec (t/day): - oil emulsion, water content 30% mass, at ∆t =25°С |

9 (777) |

28.6 (2471) |

63.2 (5443) |

|

Product temperature, °С: - at heater input, max - product output |

+5 +90 |

||

|

Efficiency factor, % |

65 |

||

|

Product coil pressure, MPa (kgf/cm2): - working, max - estimated - hydro tested |

25.0 (250) 25.0 (250) 31.3 (313) |

16 (160) 16 (160) 20 (200) |

6.3 (63) 6.3 (63) 8.2 (82) |

|

Heated medium parameters: - title - density at 20°С, kg/m3, max - viscosity at 20°С, cSt - hydrogen sulphide content (H2S), % mol., max - carbon dioxide content (СО2), % mol., max |

oil, oilemulsion 900 100

0.01

1.0 |

||

|

Fuel parameters (natural gas or associated gas): - hydrogen sulphide content (Н2S), mass fraction, % max - heat capacity MJ/m3within - pressure at heater input, MPa (kgf/cm2), within

- pressure before burners ,MPa ( kgf/cm2), within

- fuel gas consumption, nm3/sec (nm3/hr), max |

0.002 35…60 0.3…1.0 (3.0…10) 0.07…0.15 (0.7…1.5) 0.02 (76) |

0.002 35…60 0.3…1.2 (3.0…12) 0.07…0.15 (0.7…1.5) 0.08 (306) |

0.002 33.5 0.3…1.0 (3.0…10.0) 0.07…0.15 (0.7…1.5) 644 |

|

Mass, kg, max: - without intermediate heat carrier |

5500 |

14500 |

22000 |

|

Service life, years, min |

10 |

||

|

Reliability parameters: - average trouble-free life, years, min. |

3.5 |

||

|

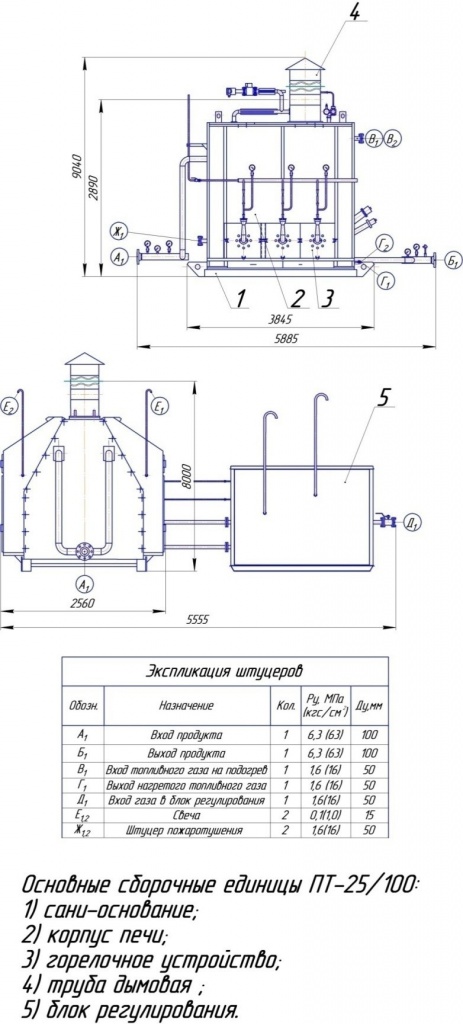

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Product inlet |

1 |

6.3 (63) |

100 |

|

Б1 |

Product outlet |

1 |

6.3 (63) |

100 |

|

В1 |

Fuel gas heating inlet |

1 |

1.6 (16) |

50 |

|

Г1 |

Fuel gas heating outlet |

1 |

1.6 (16) |

50 |

|

Д1 |

Control block gas inlet |

1 |

1.6 (16) |

50 |

|

Е1,2 |

Candle |

2 |

0.1 (1.0) |

15 |

|

Ж1,2 |

Firefighting choke |

2 |

1.6 (16) |

50 |

PT-25/100 basic assembly units:

1) skid frame;

2) furnace shell;

3) burner device;

4) fume stack;

5) adjustment block.

PT-25/100 general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Product inlet |

1 |

6.3 (63) |

150 |

|

Б1 |

Product outlet |

1 |

6.3 (63) |

150 |

|

В1 |

Fuel gas heating inlet |

1 |

1.6 (16) |

50 |

|

Г1 |

Fuel gas heating outlet |

1 |

1.6 (16) |

50 |

|

Д1 |

Control block gas inlet |

1 |

1.6 (16) |

50 |

|

Е1,2 |

Candle |

2 |

0.1 (1.0) |

15 |

|

Ж1,2 |

Firefighting choke |

2 |

1.6 (16) |

50 |

PT-16/150 basic assembly units:

1) skid frame;

2) furnace shell;

3) burner device;

4) fume stack;

5) adjustment block

PT-16/150 general drawing.

|

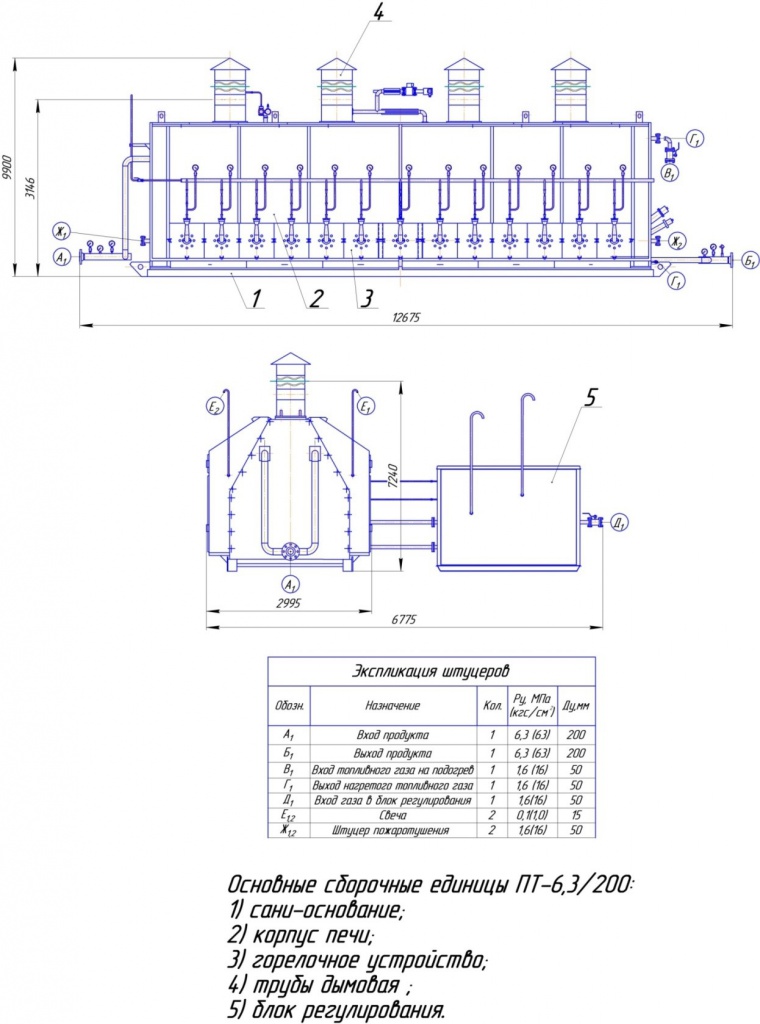

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Product inlet |

1 |

6.3 (63) |

200 |

|

Б1 |

Product outlet |

1 |

6.3 (63) |

200 |

|

В1 |

Fuel gas heating inlet |

1 |

1.6 (16) |

50 |

|

Г1 |

Fuel gas heating outlet |

1 |

1.6 (16) |

50 |

|

Д1 |

Control block gas inlet |

1 |

1.6 (16) |

50 |

|

Е1,2 |

Candle |

2 |

0.1 (1.0) |

15 |

|

Ж1,2 |

Firefighting choke |

2 |

1.6 (16) |

50 |

PT-6.3/200 basic assembly units:

1) skid frame;

2) furnace shell;

3) burner device;

4) fume stack;

5) adjustment block

PP-6.3/200 general drawing.