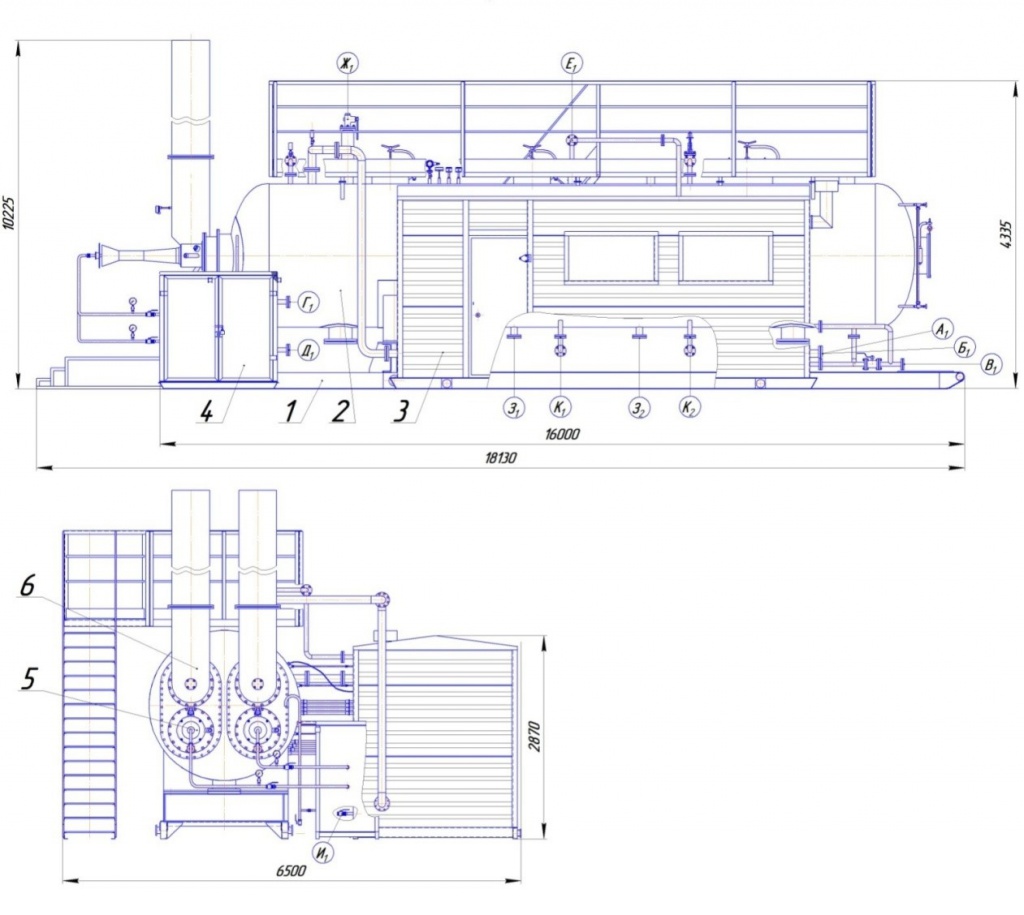

UPPN-250Мgeneral layout.

GENERAL DATA

Modular automatic oil treatment unit UPPN-M is used for efficient heating, dehydration, and demineralization of oil emulsions and stock-tank oil processing.

features

Operating conditions should correspond to U, HL by GOST 15150-69.

Placement category –1 byGOST15150-69.

Increased technical-economic values in comparison with foreign analogs due to following technical and technologicalч solutions:

- simple oil treatment process scheme;

- power saving;

- purchase and assembly of a single multifunctional unit;

- special design furnace units with antirust layer;

- better wash off minerals from oil;

- increased efficiency of well product separation;

- reduced cost of object construction;

- less service staff required;

- optimal solution for small oil fields.

Common specifications

|

Parameter |

Value |

||

|

UPPN-1000М |

UPPN-500М |

UPPN-250М |

|

|

Rated heat capacity, MW |

1.25 |

0.63 |

0.3 |

|

Oil emulsion related productivity, at water content 20% mass, t/day (kg/sec) |

1000 (9.3) |

250…500 (2.8…5.78) |

125…250 (1.4…2.89) |

|

Oil emulsion heating temperature, °С: - at unit input, max - product heating, max |

+5 +70 |

||

|

Efficiency factor, %, max |

80 |

||

|

Pressure, MPa (kgf/cm2): - working, max - estimated - hydro tested |

0.6 (6.0) 0.6 (6.0) 0.8 (8.0) |

||

|

Fuel parameters: - title - combustion heat, MJ/nm3 - hydrogen sulphide content (H2S), % mass. max - pressure gas at unit input, MPa(kgf/cm2), within - pressure before burner, MPa (kgf/cm2), within |

Natural / associated oil gas 35…60 0.002

0.2…0.6 (2.0…6.0) 0.07…0.15 (0.7…1.5) |

||

|

- fuel consumption, m3/hr |

180 |

90 |

50 |

|

Heated medium parameters: - title - viscosity at 20°С, m2/sec (cSt), max - water at unit output, mass. fraction%, max - concentration of chlorine salts at uint input, mg/dm3, max - concentration of chlorine salts at uint output, mg/dm3, max - sweet water consumption for desalting , t/hr, within - increase of sweet water pressure on unit working pressure, MPa (kgf/cm2) |

Oil emulsion 50·10-6 (50) 0.5

10000

100 0.5…1.0

0.01 (0.1) |

||

|

Mass, kg, max: - unit (in idle state) |

35000 |

20000 |

12000 |

|

Service life, years, min |

10 |

||

|

Average overhaul life, years |

3.5 |

||

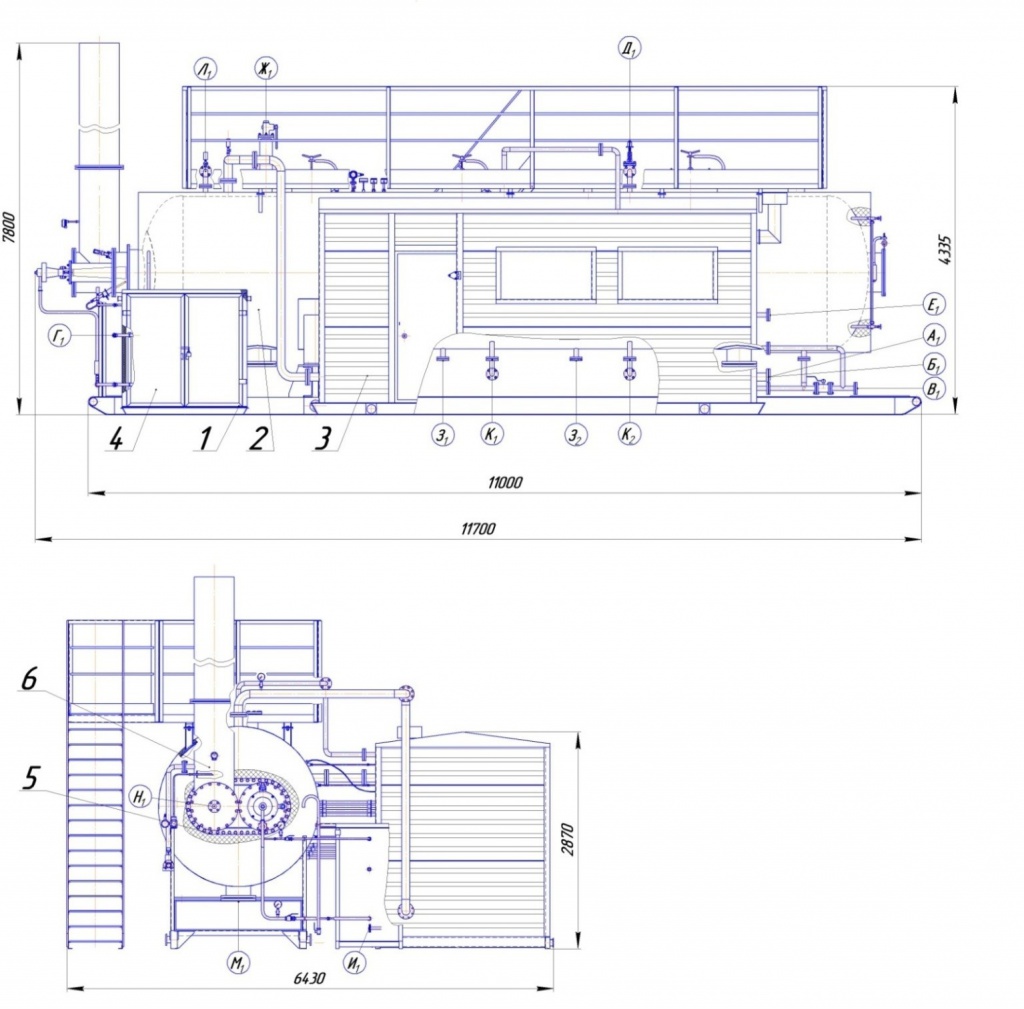

1) skid frame;

2) process block;

3) regulation block;

4) fuel treating block;

5) burner device;

6) fume stack

UPPN-1000М general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil & gas mixture inlet |

1 |

6.3 (63) |

150 |

|

Б1 |

Oil outlet |

1 |

6.3 (63) |

150 |

|

В1 |

Water outlet |

1 |

1.6 (16) |

80 |

|

Г1 |

Fuel gas inlet |

1 |

1.6 (16) |

50 |

|

Д1 |

Gas outlet |

1 |

1.6 (16) |

50 |

|

Е1 |

Sweet water inlet |

1 |

1.6 (16) |

50 |

|

Ж1 |

Safety valve discharge |

1 |

1.6 (16) |

200 |

|

З1,2 |

Drainage |

2 |

1.6 (16) |

80 |

|

И1 |

Drainage |

1 |

1.6 (16) |

25 |

|

К1,2 |

Intermediate level discharge |

2 |

0.1 (1.0) |

50 |

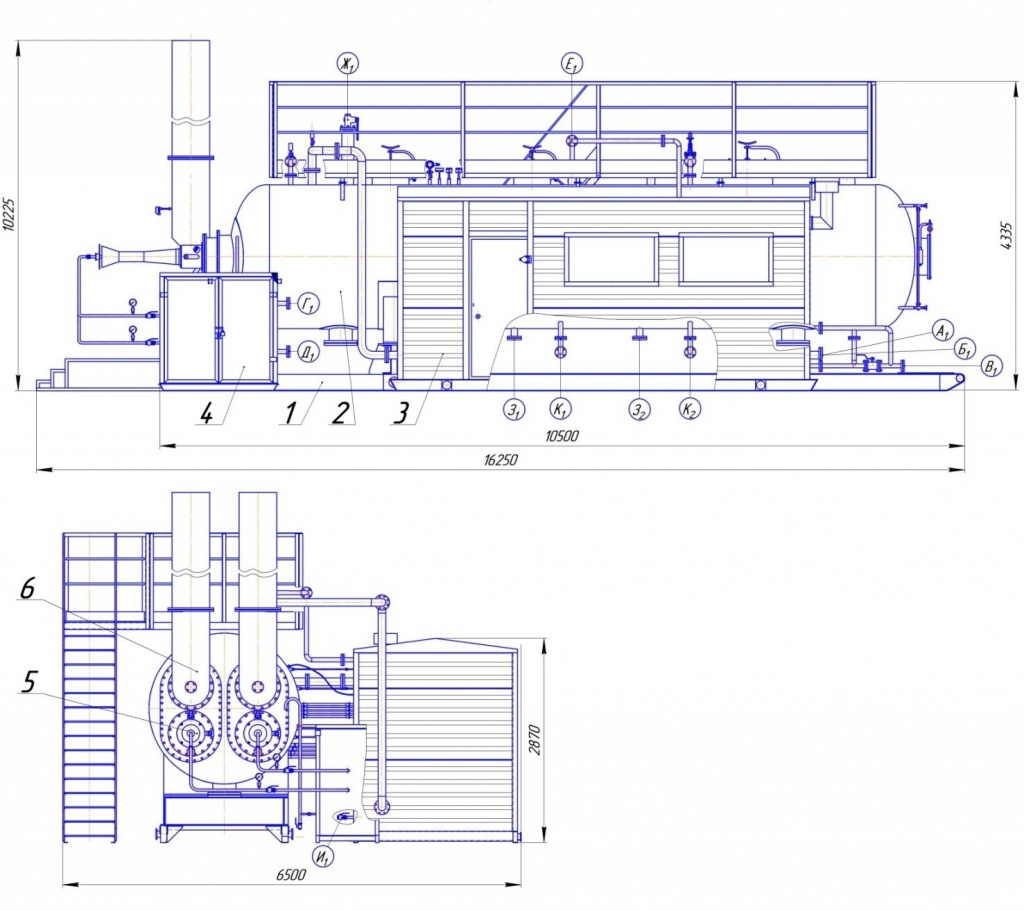

UPPN-500M basic assembly units:

1) skid frame;

2) process block;

3) regulation block;

4) fuel treating block;

5) burner device;

6) fume stack

UPPN-500М general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil & gas mixture inlet |

1 |

6.3 (63) |

150 |

|

Б1 |

Oil outlet |

1 |

6.3 (63) |

150 |

|

В1 |

Water outlet |

1 |

1.6 (16) |

80 |

|

Г1 |

Fuel gas inlet |

1 |

1.6 (16) |

50 |

|

Д1 |

Gas outlet |

1 |

1.6 (16) |

50 |

|

Е1 |

Sweet water inlet |

1 |

1.6 (16) |

50 |

|

Ж1 |

Safety valve discharge |

1 |

1.6 (16) |

200 |

|

З1,2 |

Drainage |

2 |

1.6 (16) |

80 |

|

И1 |

Drainage |

1 |

1.6 (16) |

25 |

|

К1,2 |

Intermediate level discharge |

2 |

0.1 (1.0) |

50 |

UPPN-250M basic assembly units:

1) skid frame;

2) process block;

3) regulation block;

4) fuel treating block;

5) burner device;

6) fume stack

UPPN-250М general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil & gas mixture inlet |

1 |

1.6 (16) |

100 |

|

Б1 |

Oil outlet |

1 |

100 |

|

|

В1 |

Water outlet |

1 |

50 |

|

|

Г1 |

Fuel gas inlet |

1 |

25 |

|

|

Д1 |

Gas outlet |

1 |

50 |

|

|

Е1 |

Sweet water inlet |

1 |

50 |

|

|

Ж1 |

Safety valve discharge |

1 |

200 |

|

|

З1,2 |

Drainage |

2 |

50 |

|

|

И1 |

Drainage |

1 |

25 |

|

|

К1,2 |

Intermediate level discharge |

2 |

0.1 (1.0) |

50 |

|

Л1 |

Gas inlet |

1 |

1.6 (16) |

50 |

|

М1,2 |

Sludge removal |

2 |

- |

300 |

|

Н1 |

Firefighting choke |

1 |

- |

50 |