The furnace designed for heating and partial evaporation of diesel fraction coming from column cubeТ-401, with subsequent return into T-401 column as a “hot stream”.

features

Operation conditions should correspond to U, HL by GOST 15150-69.

Placement category –1 by GOST15150-69.

Maximal block installation area seismic activity – 6 points by SNiP 11-7-81.

The furnace has 2 coils:

1) Coil №1 works with diesel fraction;

2) Coil №2 works with fuel gas.

COMMON SPECIFICATIONS

Common specifications presented in tables below.

Coil 1 specification list.

|

Parameter |

Value |

|

Nominal heat release, MW |

1.056 |

|

Diesel fraction related productivity, kg/hr |

22285 |

|

Temperature, °С: - at furnace input, within; - at furnace output, max; - wall temperature, designed; - coil walls, min allowable |

+304 +328 +440 minus 47 |

|

Coil pressure, MPa (kgf/cm2): - process; - working, max; - designed; - hydro tested. |

0.5…0.6 (5.0…6.0) 0.77 (7.7) 0.8 (8.0) 1.47 (14.7) |

|

Heated medium parameters: - title; - hazard class; - explosion risk; - fire risk; - explosion hazard zone class. |

diesel fraction 4 by GOST 12.1.007-76 yes yes 2 by GOST Р 51330.9-99 |

|

Corrosion allowance, mm |

2 |

|

Radiant tube heating surface area, m2 |

40.6 |

|

Service life, years, min: - coil; - furnace. |

10 15 |

|

Furnace mass, kg max: - in idle state; - during hydro test. |

23000 25130 |

Coil 2 specification list.

|

Parameter |

Value |

|

Nominal heat release, MW |

1.056 |

|

Fuel gas related productivity, m3/hr |

61±15% |

|

Temperature, °С: - at furnace input, within; - wall temperature, designed; - coil walls, min allowable |

+40…+50 +70 minus 47 |

|

Coil pressure, MPa (kgf/cm2) : - process |

0.01…0.1 (0.1…1.0) |

|

Heated medium parameters - title; - hazard class; - explosion risk; - fire risk; - explosion hazard zone class. |

fuel gas 4 by GOST 12.1.007-76 yes yes 2 by GOST Р 51330.9-99 |

|

Corrosion allowance, mm |

2 |

|

Service life, years, min: - coil; - furnace. |

10 15 |

|

Furnace mass, kg max: - in idle state; - during hydro test. |

23000 25130 |

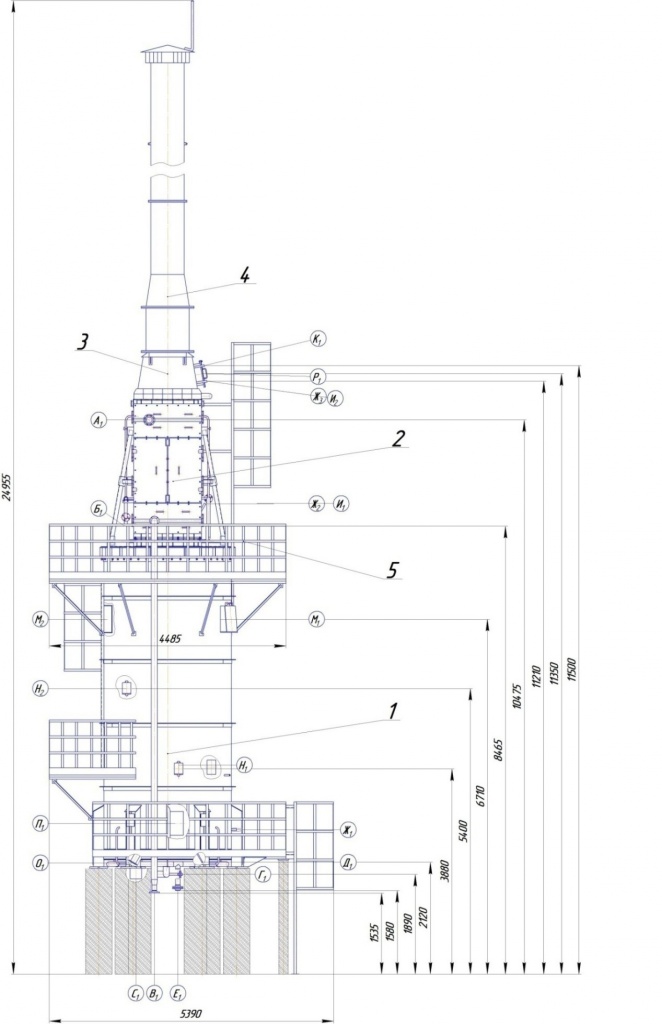

N-402 basic assembly units:

1) radiant section;

2) convection section;

3) regulating gate;

4) fume stack;

5) platform.

N-402 general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal Pressure, MPa (kgf/cm2) |

DN, mm |

|

A1 |

Product inlet |

1 |

1.6 (16) |

100 |

|

Б1 |

Product outlet |

1 |

150 |

|

|

В1 |

Drainage |

1 |

80 |

|

|

Г1 |

Burner fuel gas inlet |

1 |

32 |

|

|

Д1 |

Primer installation choke |

1 |

15 |

|

|

Е1 |

Gas or nitrogen input |

1 |

80 |

|

|

Ж1, 2, 3 |

Underpressure measurement |

3 |

- |

15 (M20x1.5)

|

|

И1,2 |

Heat converter installation choke |

2 |

||

|

К1 |

Fume gas analyzer installation choke |

1 |

|

M16 |

|

Л1 |

Photosensor installation choke |

1 |

|

80 |

|

М1, 2 |

Exhaust window |

2 |

|

500 |

|

Н1 |

Inspection hole |

3 |

|

150x220 |

|

О1 |

Bottom inspection hole |

1 |

|

100 |

|

П1 |

Manhole hatch |

1 |

|

450x540 |

|

Р1 |

Observation hole |

1 |

|

400 |

|

С1 |

Sanitation hole |

1 |

|

200 |