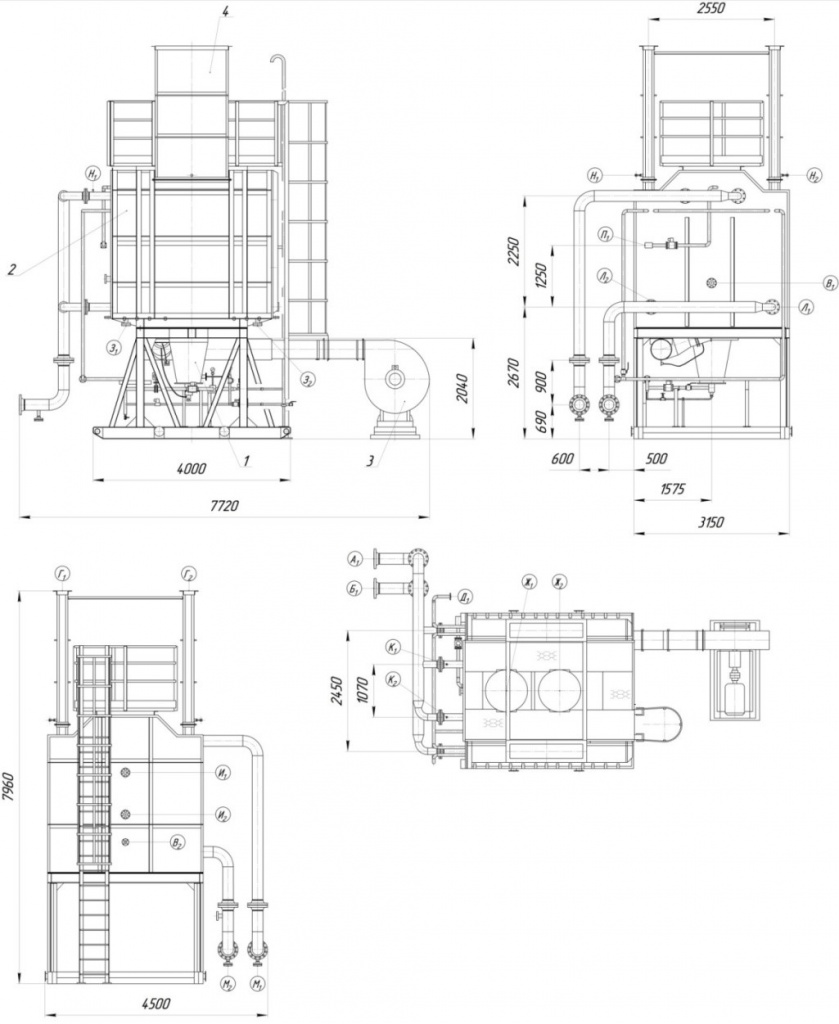

PPN-3 heat exchange chamber general layout.

GENERAL DATA

Modular tube furnace PPN-3 intended for heating of oil and oil emulsions during their infield transportation and treatment.

PPN-3 features

Climatic modification – U, HL by GOST 15150-69.

Placement category–1 by GOST15150-69.

Common specifications

|

Parameter |

Value |

|

Rated heat capacity, MW |

3.0 |

|

Oil emulsion related productivity, t/hr (kg/sec), within |

62.5…125 (17.4…34.7) |

|

Product temperature, °С: - at furnace input, min - at furnace output, max. |

+5 +90 |

|

Efficiency factor,% , max |

80 |

|

Product coil pressure, MPa (kgf/cm2): - working, max - estimated - hydro tested |

6.3 (63) 6.3 (63) 8.2 (82) |

|

Fuel parameters: - title - hydrogen sulphide content (H2S), % mass. max - furnace input pressure, MPa (kgf/m2), max - pressure before combustion chamber, MPa, within - air pressure inside combustion chamber, kPa - gas pressure before primer burner, MPa, within - primer burner fuel gas consumption, nm3/hr (nm3/sec) - fuel gas consumption, nm3/hr - air consumption, nm3/hr |

Natural / associated oil gas 0.002 0.1…0.3 (1.0…3.0) 0.005…0.05 3.0 0.06…0.18 3.0 (0.00085) 400 6000 |

|

Fuel parameters (diesel fuel, oil): - lower combustion heat, kcal/kg - hydrogen sulphide content (H2S), mass fraction, % max - pressure before nozzle, MPa (kgf/cm2), max - fuel consumption, kg/hr, |

6800 0.002

4.0 (40.0) 800 |

|

Number of combustion chambers |

2 |

|

Mass, kg, max: - furnace (in idle state); - heat exchange chamber; - furnace foundation block; - ventilation set block |

24600 15000 4000 1500 |

|

Service life, years, min |

10 |

|

Average overhaul life, years |

3.5 |

1) furnace foundation block;

2) heat exchange chamber;

3) ventilator set block

4) fume stack

PPN-3 general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil inlet |

1 |

4.0 (40) |

200 |

|

Б1 |

Oil outlet |

1 |

4.0 (40) |

200 |

|

В1,2 |

Firefighting (nitrogen) choke |

2 |

1.6 (16) |

50 |

|

Г1,2 |

Fume gasoutlet |

2 |

200x1000 |

|

|

Д1 |

Gas inlet from GRP |

1 |

0.6 (6) |

50 |

|

Ж1,2 |

Safety valve |

2 |

- |

700 |

|

З1,2 |

Heat exchange chamber drainage |

2 |

0.1 (1) |

25 |

|

И1,2 |

Observation window |

2 |

- |

80 |

|

К1,2 |

Coil purge choke |

2 |

4.0 (40) |

15 (Rc 1/2) |

|

Л1,2 |

Coil medium temperature control |

4 |

- |

20 (M20x1.5) |

|

М1,2 |

Drainage of product lines |

2 |

4.0 (40) |

50 |

|

Н1,2 |

Fume gas temperature control |

2 |

- |

15 (M20x1.5) |

|

П1 |

Heat exchange chamber air sampling |

1 |

- |

50 |