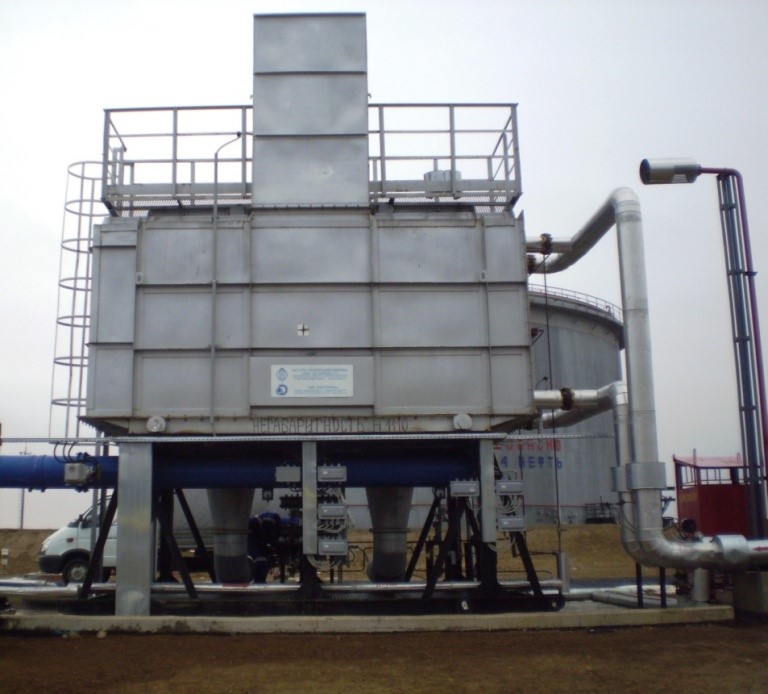

PTB-5-40Zh general layout.

GENERAL DATA

Modular tube furnace intended for heating of oil and oil emulsions during their infield transportation and treatment.

Liquid fuel furnace can be fabricated by individual order.

features

Climatic modification – U, HL by GOST 15150-69.

Placement category – 1 by GOST15150-69.

Common specifications

|

Parameter |

Value |

|||

|

PTB-5-40E |

PTB-5-63E |

PTB-5Zh |

||

|

Rated heat capacity, MW |

3.5…7.3 |

|||

|

Oil emulsion related productivity, t/hr (kg/sec), within |

125…250 (34.7…69.5) |

|||

|

Product temperature, °С: - at furnace input, min - at furnace output, max. |

+5 +90 |

|||

|

Efficiency factor,% , max |

80 |

|||

|

Product coil pressure, MPa (kgf/cm2): - working, max - estimated - hydro tested |

4.0 (40) 4.0 (40) 5.0 (50) |

6.3 (63) 6.3 (63) 8.2 (82) |

||

|

Fuel parameters: - title - hydrogen sulphide content (H2S), % mass. max - furnace input pressure, MPa (kgf/m2), max - pressure before combustion chamber, MPa, within - air pressure inside combustion chamber, kPa - gas pressure before primer burner, MPa, within - primer burner fuel gas consumption, nm3/hr (nm3/sec) - fuel gas consumption, nm3/hr - air consumption, nm3/hr |

Natural / associated oil gas 0.002 0.1…0.3 (1.0…3.0) 0.005…0.05 3.0 0.06…0.18 3.0 (0.00085) 800 12000 |

|||

|

Fuel parameters (diesel fuel, oil): - lower combustion heat, kcal/kg - hydrogen sulphide content (H2S), mass fraction, % max - pressure before nozzle, MPa (kgf/cm2), max - fuel consumption, kg/hr, |

- |

6800 0.002

4.0 (40.0) 800 |

||

|

Number of combustion chambers |

2 |

|||

|

Mass, kg, max: - furnace (in idle state); - heat exchange chamber; - furnace foundation block; - ventilation set block |

25350 18595 5160 1500 |

|||

|

Service life, years, min |

10 |

|||

|

Average overhaul life, years |

3.5 |

|||

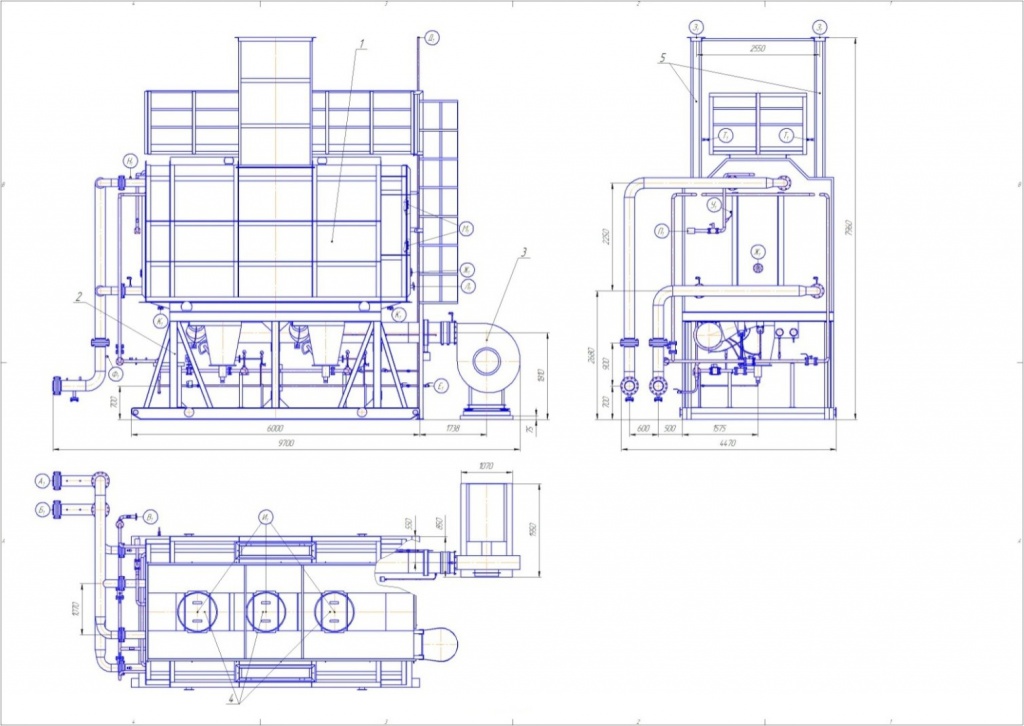

1)heat exchange chamber;

2)furnace foundation block;

3)ventilator set block

4)explosive valve block;

5)fume stack;

PTB-5-40Egeneral drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil inlet |

1 |

4.0 (40) |

200 |

|

Б1 |

Oil outlet |

1 |

4.0 (40) |

200 |

|

В1 |

Fuel gas inlet |

1 |

0.6 (6) |

50 |

|

Д1 |

Candle |

1 |

- |

50 |

|

Е1 |

Condensate discharge |

1 |

- |

25 |

|

Ж1 |

Heat exchange chamber steam (nitrogen) inlet |

2 |

1.6 (16) |

50 |

|

З1 |

Fume gas outlet |

2 |

- |

200x1500 |

|

И1 |

Safety valve |

3 |

- |

700 |

|

К1 |

Heat exchange chamber drainage |

2 |

0.1 (1) |

25 |

|

Л1 |

Heat exchange chamber pressure sampling |

1 |

- |

50 |

|

М1 |

Observation window |

2 |

- |

80 |

|

Н1 |

Coil purge choke |

2 |

4.0 (40) |

15 (Rc 1/2) |

|

П1 |

Heat exchange chamber air sampling |

1 |

- |

50 |

|

Р1 |

Coil medium temperature control |

4 |

4.0 (40) |

20 (M20x1.5) |

|

С1 |

Drainage of oil lines |

2 |

4.0 (40) |

50 |

|

Т1 |

Fume gas temperature control |

2 |

- |

15 (M20x1.5) |

|

У1 |

Air temperature control inside heat exchange chamber line |

1 |

- |

25 (M20x1.5) |

|

Ф1 |

Oil heating temperature control (thermotransducer TSMU) |

1 |

4.0 (40) |

15 (M20x1.5) |